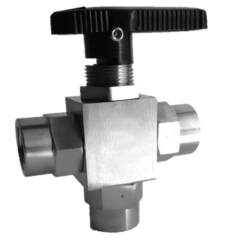

Description

Typical Applications of Needle Valve (Isolation and Venting of other instruments):

- Instrumentation Systems

- Oil and Gas Applications

- Gas Distribution Systems

- Power Plants and Refineries

- Pressure Gauge Valves

- Test Stands

Testing:

Each Needle Valve is factory tested with nitrogen gas at 1000psig (69 Bar) for leakage at seal & seat. Other optional tests like hydrostatic (1.5 times of the working pressure) and helium leak tests are available upon request.

Materials of Construction:

| Sr. no. | Component | Material |

| 1 | Body | SS316 / A276 |

| 2 | Bonnet | SS 316 |

| 3 | Vee/Regulating Stem Tip | SS316 / 17-4 PH |

| 4 | Stem Packing | PTFE |

| 5 | O-ring | Viton |

| 6 | Stem | SS316 / A276 |

| 7 | Check Nut | SS 304 |

| 8 | Packing Nut | SS316 |

| 9 | Grub Screw | CS |

| 10 | Bar Handle | SS 304 |

| 11 | Stopper Pin | SS 304 |

| 12 | Dust Cap | Nylon |

Part Number and details:

| Part Number | Inlet x outlet connections | Orifice Size in mm | Dimensions in mm | |||

| L | D | A | L1 | |||

| NVV6-SS4MF | 1/4″ NPT (M)x (F) | 4 | 70 | 25 | 62 | 45 |

| NVV6-SS6MF | 3/8″ NPT (M)x (F) | 4 | 70 | 25 | 62 | 45 |

| NVV6-SS8MF | 1/2″ NPT (M)x (F) | 5 | 75 | 30 | 84 | 55 |

Reviews

There are no reviews yet.