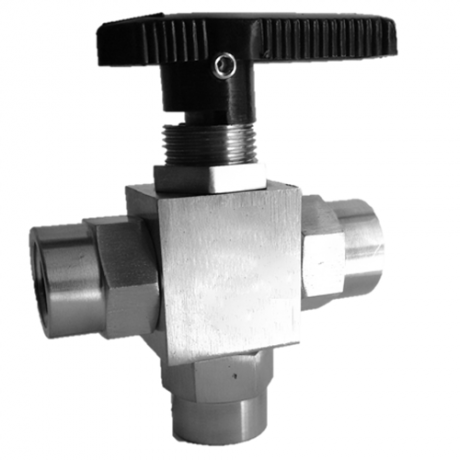

Description

Typical Applications of the I series 3 way:

- Sampling Systems

- Pneumatic Test Bench

- R& D Laboratories

- Gas and Liquid Applications

- Pilot Plants

- ON-OFF Switching Applications

Testing:

Each I series 3 way ball valve is factory tested with nitrogen gas at 1000 psig (69 Bar) for leakage at seat. Other optional tests like hydrostatic (1.5 times of the working pressure) and helium leak tests are available upon request.

Materials of Construction for Stainless Steel Valves:

| Sr. no. | Component | Material |

| 1 | Body | SS316 / A479 |

| 2 | Adaptor | SS316 / A479 |

| 3 | Ball | SS316 / A479 |

| 4 | Stem | SS316 / A479 |

| 5 | Seats | PTFE |

| 6 | Seals | Viton |

| 8 | Nut | SS316 |

| 9 | Stop Pin | SS316 |

| 10 | Handle | Nylon |

| 11 | Nut | SS316 |

| 12 | Ferrules | SS316 |

| 14 | Dust Cap | Nylon |

Ordering:

| Part Number | Inlet/outlet connections | Orifice Size in mm | Dimensions in mm | |

| L | H | |||

| IBVX6-SS2T | 1/8″ Tube OD | 2.5 mm | 51 | 59 |

| IBVX6-SS4T | 1/4″ Tube OD | 5 mm | 60 | 67 |

| IBVX6-SS6T | 3/8″ Tube OD | 7 mm | 74 | 89 |

| IBVX6-SS8T | 1/2″ Tube OD | 10 mm | 90 | 106 |

| IBVX6-SS12T | 3/4″ Tube OD | 15 mm | 90 | 106 |

Reviews

There are no reviews yet.